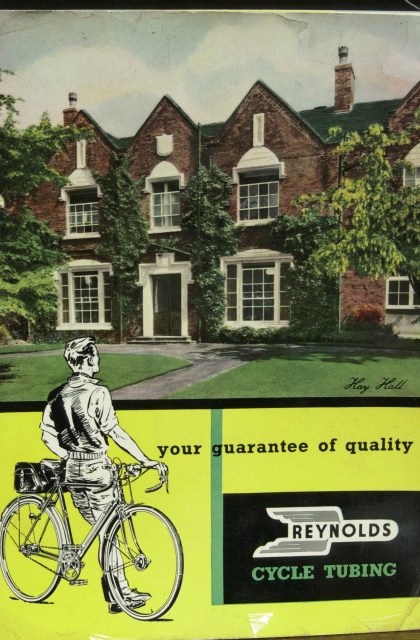

Reynolds catalogue from the 1970's. The introduction reads: "Over fifty years have passed since Reynolds made lightweight cycling possible by the introduction of the butted tube. This process, as is now well-known, enabled the greater thickness of metal to be distributed at the joints of the cycle frame without imposing the same weight penalty over the whole length of the tube.

The butted tube is still in great demand to-day, but great progress has been made in improving steel specifications to the present high standard of REYNOLDS 531 tubing, details of the products made in this material being fully described in the Catalogue.

To-day we are justly proud of the contribution Reynolds makes to lighter cycling, and the international repute of our REYNOLDS 531 tubing, which is specified wherever a combination of strength and lightness is required."

The Reynolds 531 material, introduced in 1935 was the tube which set the standard for road, track and touring frames for many years. Today however, 531 has been largely supplanted by the seamless air hardening steels with ultimate tensile strengths between 180-210Ksi (1250-1450 MPa) for 853 and between 115-130Ksi (800-900MPa) for 631. Quoting a new Reynolds brochure, "The production process ensures tight tolerance, thin gauge tubes. The strength to weight ratio of the air hardening steels (853 & 631) is equal to that of quality titanium and aluminum frames. A normal chrome molybdenum steel will lose strength in the joints after the heat has been applied. This material (853 & 631) INCREASES in strength (when heated to around 850 degrees C (1560 degrees F) and the recommended braze metal per AWS Classification, RBCuZn type is applied) as the frame cools to strengths well in excess of the as delivered values shown above. This unique air hardening property of Reynolds 853 and 631 provides additional stiffness through reduced microyielding at the joints, allowing stiffer frames with excellent fatigue strength (when compared to standard chrome molybdenum and excellent ride quality to be constructed." Please look over some of the Reynolds steel tubing offered in this section. To order, please contact Andy Newlands on 503-224-1215 or email andy@strawberrybicycle.com.