| Mechanique |

|

Album: Untitled

Last change: 12/02/15

Contains 0 items. |

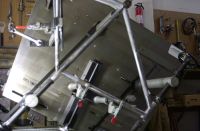

Wishbone rear triangle alignment. Once the wishbone rear triangle (topstay tube brazed to the wishbone casting and the seatstay pair brazed to the casting) any heat distortion is checked and some gentle persuasion is applied to ensure that the tube centerlines are in plane.

Viewed: 5925 times.

|

Chainstay Mitreing 001

Viewed: 4843 times.

|

|

Chainstay Mitreing 002

Viewed: 4438 times.

|

Chainstay Mitreing 003

Viewed: 4350 times.

|

Chainstay Mitreing 005

Viewed: 4230 times.

|

|

Chainstay Mitreing 008

Viewed: 4204 times.

|

Chainstay Mitreing 010

Viewed: 4419 times.

|

I met Danielle Schon at the 2016 NAHBS who displayed a beautiful track bike. Danielle gave me her sticker which I stuck on my Marchetti mitreing machine for good luck.

Viewed: 5124 times.

|

|

Donald's frame is back in the Marchetti fixture after the main diamond brazing is completed, flux soaked and roughly sandblasted and filed. The photo shows a little clamp held on the centerline of the left rear dropout which supports a ruler which extends up to the back of the seat lug. A machinists protractor is used to determine the topstay binder/cap mitre angle by measuring between the ruler and the seat tube. Tomorrow the machine mitreing of the topstay cap and the rear wishbone brazing will be photographed and uploaded.

Viewed: 5010 times.

|

Gary McKenzie and I are working on a prototype brazed carbide tube mitre cutter with help from Prince & Izant. So far the 4140 cutter blank is turned and the carbide rings are to hand so it won't be too long until the filler metal is formed for brazing the carbide to the blank.

Viewed: 4855 times.

|

Soon to be a brazed carbide tube mitre cutter. Carbide ring has been positioned for the photo. Given that the brazing is satisfactory for the cutter stresses, this little beauty should do a number on Reynolds air handening heat treated 853 material and it is hoped on the stainless 921 and 953 which has a hardness value of HRC 52 or so.

Viewed: 4959 times.

|

|

Prototype brazed carbide (top darker grey ring) tube mitre cutter. Prince and Izant provided the brazing rod and black flux and I turned a preform ring and brazed up the composite. The good news is that the carbide ring did not crack on either heating or cooling. Now Gary McKenzie will grind in the teeth and the outside diameter and then the testing on some hard material will take place back in the Strawberry workshop.

Viewed: 4883 times.

|

One last mechanical turn on the brazed carbide mitre cutter. The o.d. of the cutter body has been turned to match the carbide ring and the i.d. has been bored so all is ready for McKenzie Tool Grinding to apply their diamond grinding tools and spruce this to specification.

Viewed: 4849 times.

|

Finally returned to Donald's frame. The wishbone top stay binder was machine mitred with a 31mm T&F mitre cutter to precisely match the outside diameter of the seat lug. The top stay is then cut to length and a brass preform ring is inserted before the binder and stay are fluxed. Brazing of the binder to the top stay is done in the Marchetti fixture with the wishbone rear triangle held upside down to help the brass flow and completely wet the inside of the stay and the binder. The rear triangle will now be removed from the fixture, dunked in the flux soaking tank and finish filed.

Viewed: 4820 times.

|

|

Close up of the top stay/seat lug binder brazing. Brass preform is used for this joint and silver will be used to braze the binder to the seat lug.

Viewed: 4999 times.

|

Side view of Donald's frame held in the Marchetti fixture during brazing of the top stay and the seat lug binder.

Viewed: 4940 times.

|

Finish filing the top stay/seat lug binder joint for Donald's frame.

Viewed: 4955 times.

|

|

[RSS] |