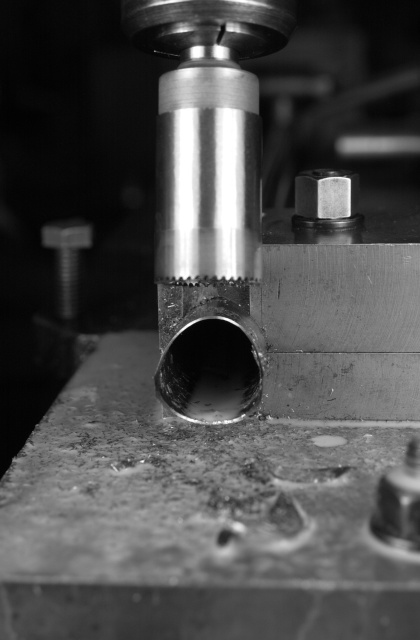

First test of the brazed carbide tube mitre cutter on Reynolds 953 stainless steel heat treated cycle frame tubing no. SS4000 (28.6x0.5/0.3/0.5) with HRC52. (Carbide hardness is in the range of 90-91 HRC. High tooth count diamond wheel ground by Gary McKenzie and the cutter body is 4140 steel turned in the Strawberry workshop by Andy.) Cut was indistinguishable from the cut of the 631 air hardening non heat treated steel tube. Hand fed at 325 rpm, cut time 11 seconds, painted-on Blasocut 4000 Strong coolant employed on my trusty 1957 model Bridgeport milling machine. Good news indeed.