| Mechanique :: slit03 |

|

Mechanique |

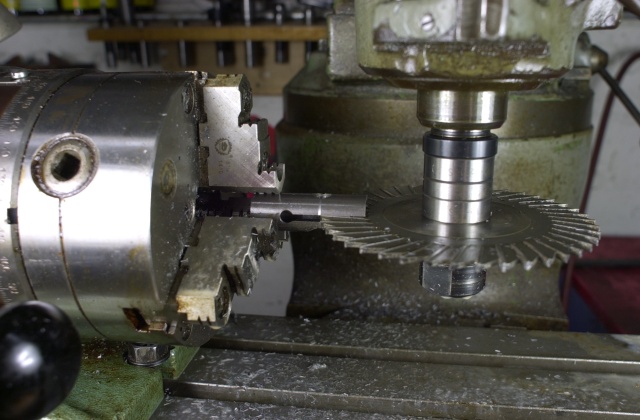

Slitting operation on the wishbone topstay seatpost binder using the Super Indexing Spacer and a 5/32" x 6" side cutting slitting saw. The 7/8" diameter 4130 steel rod has been coldsawn, thru drilled, bored, grooved, countersunk for the 10mm button head capscrew, chamfered, slit, threaded and then lathe turned on the back end to fit the topstay. All done on manual machines. No CNC machines when the demand is low!

|

Mechanique |

|

[RSS] |